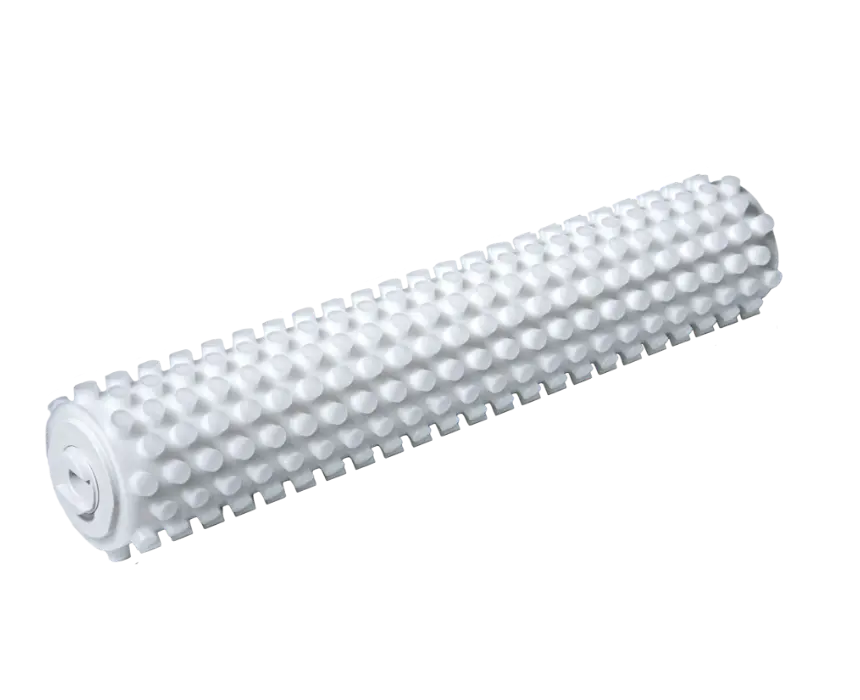

Semiconductor Brush Rollers

Post-CMP Cleaning

Following chemical mechanical polishing (CMP), inorganic, organic, and chemical residues remain on the wafer surface that can cause defects if not removed. PVA brush rollers provide a gentle, scratch-free cleaning solution while maintaining their flexible structure even after absorbing liquids. The brush delivers cleaning chemicals and deionized water to the wafer surface, rolling and scrubbing for effective continuous cleaning and drying.

Features

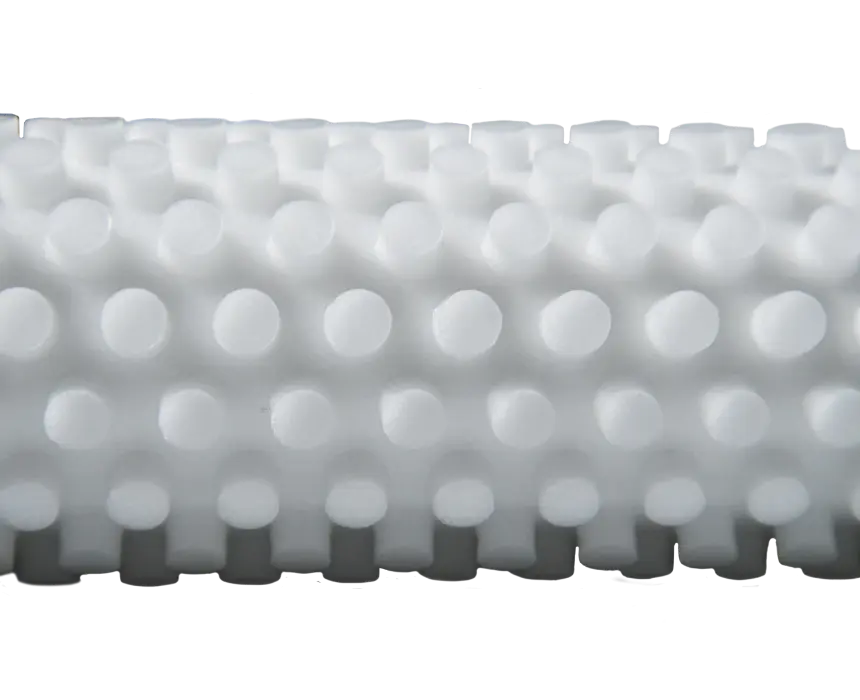

- Air-foaming technology: No starch residues.

- Industry-leading capabilities for detecting minimum metal and liquid particles.

- Energy efficient: Cuts CMP water usage by 10%, reduces energy consumption in wastewater treatment.

Enhanced utilization: Significantly reduces pre-cleaning break-in time, minimizing dummy wafer usage.

- One-piece design: Molded PVA foam and core reduce distortion risk.

- Excellent liquid transmissibility and self-clean ability: 100% interconnected pore structure for superior cleaning.

- Customizable: Adjustable water flow for optimized cleaning.

World's Only Air-Foamed PVA Brush Rollers

| Ultra Clean | Highly Compatible | ESG DNA |

|---|---|---|

|

|

|

Applications

Brush rollers for post-CMP cleaning.

Specifications

For detailed specifications, please contact us.